ENOIN New Material Technology Resists Electric Arc Fires, Moisture Condensation, Harsh Environments, etc., Providing Full Life-Cycle Protection for Power Grid Assets!

- Hotline:86 19331265159

- [email protected]

Overhead Line Facilities

- ENOIN Provides High-Performance Insulation, Waterproofing, Fireproofing, and Standardized Products for Overhead Line Facilities, Ensuring More Reliable, Safer, and Stable Power Transmission.

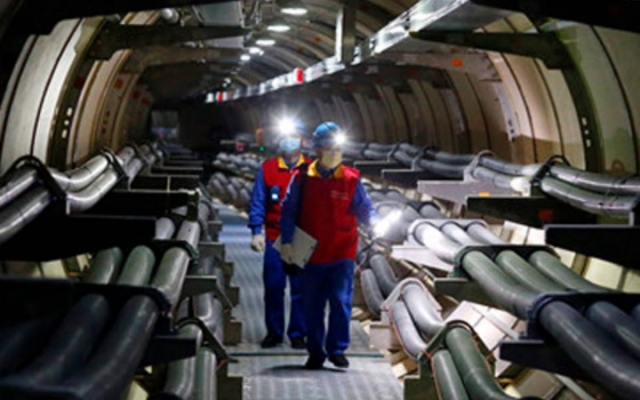

Underground Cable Systems

- Underground cable failures constitute critical vulnerabilities in power networks, where ENOIN's high-performance MRO materials deliver system resilience enhancement.

Renewable Power Generation

- ENOIN’s New Material Maintenance Solutions Support the Stable Operation of Renewable Power Generation Systems, Preventing Power Generation Losses Caused by Insulation Issues, Fires, Moisture, External Forces, and More.

Rail Transit

- The power supply systems of subways and high-speed railways are critical, and the high-performance, specialized ENOIN operation and maintenance solutions support smooth and uninterrupted rail transit as well as rapid recovery.