- Corrosion and Water Ingress in Cable Joints and Bodies: Leading to frequent faults.

- Water Seepage and Corrosion Through Cable Trench Walls and Floors: Including main structures or gaps.

- Short Circuit Arcs Leading to Fires: Especially in densely cabled areas where fires can spread quickly.

- Inadequate Sealing of Cable Conduits and Isolations: Main points of water ingress.

- Accumulation of Water in Cable Trenches: Causing moisture condensation affecting both primary and secondary equipment.

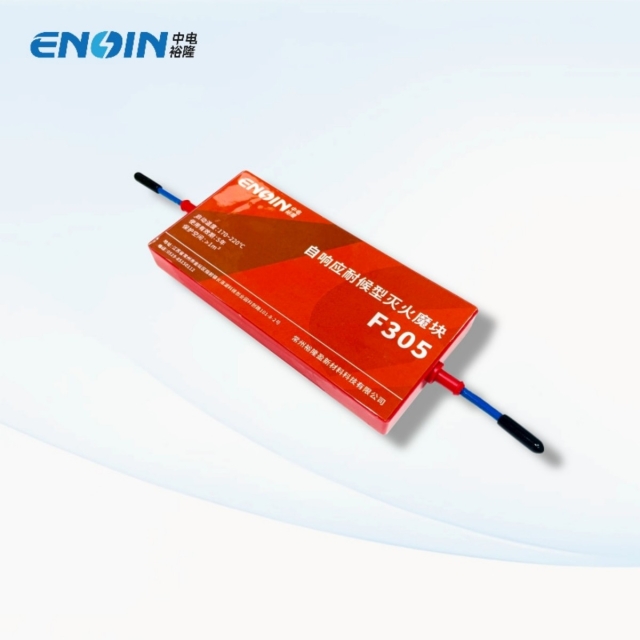

- Comprehensive Performance Improvement for Cable Joints and Bodies: Utilizing high-performance "four-in-one" gel (insulation, waterproofing, fireproofing, anti-corrosion) and passive weather-resistant fire extinguishing modules to provide comprehensive protection.

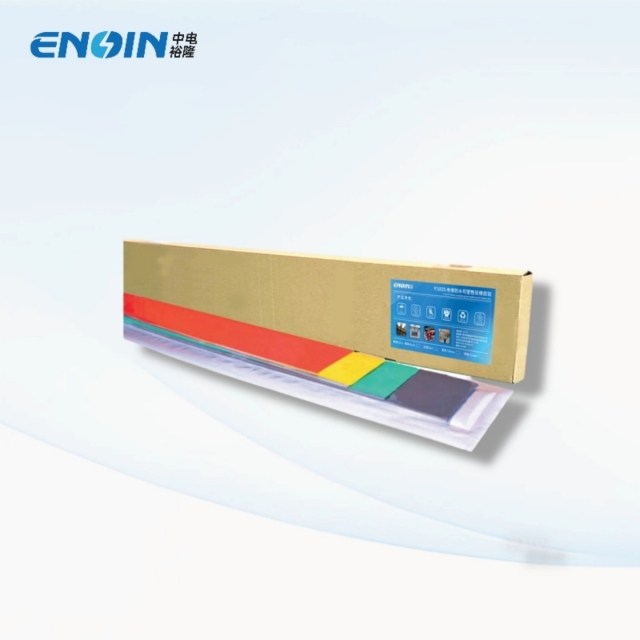

- Enhanced Sealing Performance of Cable Conduits and Isolations: High-expansion resin conduit sealing kits offer quick installation, adaptability to various hole sizes, and excellent leak prevention effects.

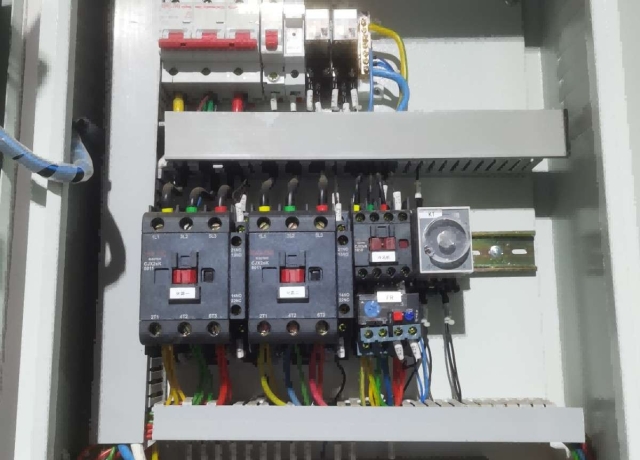

- Elimination of Moisture Condensation in Primary and Secondary Equipment: Materials tightly bond with metal surfaces, effectively sealing gaps between the floor and cables, preventing moisture intrusion.

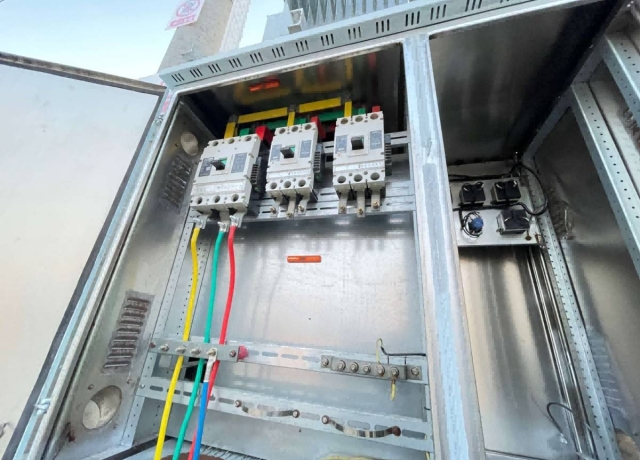

- Resolution of Water Seepage Issues in Cable Trench Walls and Floors: Application of inorganic super-hydrophobic cement-based moisture barrier coatings creates an efficient waterproof barrier, preventing structural corrosion caused by water penetration.

- Prevention of Fire Spread in Underground Cables: Automatic fire extinguishing modules or fire extinguishing ropes can quickly suppress initial fires in densely cabled areas. They interrupt the chain reaction of burning, control the spread of fire, and reduce fire risks.